Table of Contents

Positive displacement compressors are used for different industrial and residential applications. Positivedisplacement compressors have multiple types, and a scroll compressor is one of them. The scroll compressor is also known as a scroll pump, scroll vacuum pump, or spiral compressor. The scroll compressor concept has been used for a long time, but recent developments in manufacturing technology have made them more viable. This article mainly explains the working, types, and applications of screw compressor.

What is a Scroll Compressor?

A scroll compressor is a compressor that uses two or more spiral-shaped scroll piecesfor the compression of the working fluid. These scrolls move in a circular motion instead of upward and downward motion as piston action in a reciprocating compressor.

Out of two scrolls, one scroll is a rotatory scroll that rotates using a vibratory link while the other scroll is fixed that remains stationary. When the fluid enters the compressor, the fluid is trapped between the scrolls, and the compression process occurs when the rotatory scroll rotates.

The working and design of these compressors are very similar to the screw compressors. The screw compressor works in a similar way as the scroll compressor. It has quiet and smooth working.

These types of compressors have more efficiency and reliability than reciprocating compressors. Therefore, scroll compressors are most commonly used in HVAC systems.

One of the main advantages of the Copeland scroll compressors is that it has less torque and fewer rotating parts than piston compressors.

These compressors may utilize in a variety of ways to fulfill the requirements of the homeowners for economy, comfort, and efficiency.

What is Copeland Scroll Compressor?

The Copeland scroll compressor contains a spiral or scroll that rotates in a path guided by the corresponding stationary scroll. This stationary scroll attaches to the housing of the compressor. The moving scroll is connected to the crankshaft in orbit instead of rotating.

The simple structure of these compressors ensures their smooth and quiet operation. They don’t require a suction valve for efficient compression. Therefore, they have a quiet and smooth operation.

Working of Scroll Compressor

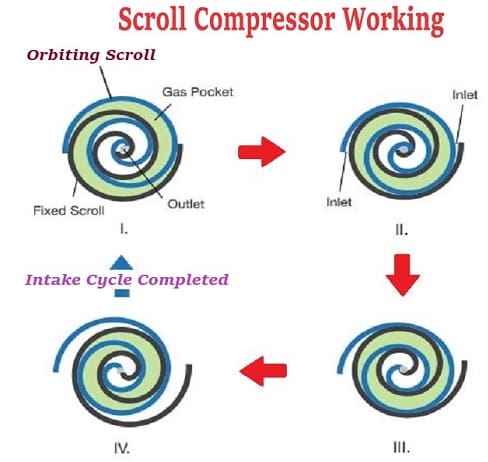

The scroll compressor works on the positive displacement principle. It has two scrolls (i.e., stationary scroll and moving scroll). In a typical construction, the moving scroll rotates 180° with respect to the stationary scroll. In this way, these scrolls mesh with each other.

The moving scroll connects to the crankshaft, while the stationary scroll connects to the compressor body. A generator or electric motor uses to drive the crankshaft.

When the drive motor supplies power to the crankshaft, it starts rotating. As the crankshaft rotates, it transfers its motion to a moving scroll and rotates it. Due to the movement of the moving scroll, a pressure difference generates between the compressor’s internal pressure and external pressure.

Due to the pressure difference, a suction force generates that introduces air from the external air storage tank to the compressor. The sucked air is trapped between the moving scroll and the stationary scroll. This trapped air can’t move directly from the suction side to the discharge side. It can only move with the scroll motion.

When the moving scroll moves, it gradually moves the trapped air toward the compressor center, reduces the air volume, and compresses it.

Eventually, the compressed air reaches the center of the assembly from where the compressed air is discharged via a port.

Read Also: Working of Screw Compressor

Design of Scroll Compressor

The scroll compressor has two meshed scrolls to pressurize, compress, or pump a fluid (such as a liquid or gas). The design of the scroll can be a hybrid curve, an Archimedean spiral, or an involute curve.

Typically, one scroll is stationary while the other scroll moves eccentrically without compressing, pumping, trapping, or rotating the fluid pockets between the scrolls.

The moving scroll links with the crankshaft while the stationary scroll is fixed with compressor housing. The stationary scroll guides the moving path of the moving scroll.

You can prevent axial gap leakage by using a volute tip seal. Install this seal in the groove of both scroll tips. These seals also reduce friction, and you can easily replace them when worn.

Some types of scroll compressors use pressurized exhaust gas to bring the two scrolls together. This method eliminates the need for a tip seal and improves the seal used.

The flexible (flat) tubing of the compressor also generates extreme vibration where the Archimedean screw works as a peristaltic pump that acts in a similar way to the toothpaste tube. Such compressor features a lubricant-filled housing that prevents wear on the outside of the compressor tube and aids in heat dissipation by using a reinforced tube commonly known as “hoses.” This type of pump is also referred to as a “hose pump.”

Peristaltic pump has low manufacturing cost because moving parts of this pump doesn’t make contact with the fluid. They have low maintenance costs because they don’t have fittings and valves.

Read Also: Different Types of Pumps

Types of Scroll Compressors

The scroll compressor has the following major types:

- Single-stage Compressor

- Two-stage Compressor

- Variable Capacity Compressor

1) Single-stage Compressor

The Single-stage scroll compressors are most commonly used in household heating and cooling applications. These types of scroll compressors have a simple structure. They have low costs. However, you can operate them at only one specific speed. They have the capability to efficiently heat or cool your building.

2) Two-stage Compressor

The two-stage compressor operates at two different speeds. These compressors have the capability to bring their heating or cooling capacity closer to the home’s exact requirements.

The two-stage compressor has the capability to operate at a slower, more efficient speed which assists in eliminating additional moisture from the air while conserving energy.

You can also switch the compressor to full power if you want to stabilize the temperature. These compressors have more efficiency than single-stage compressors.

Read Also: Different Types of Compressors

3) Variable Capacity Compressor

Rather than working in one or two stages, variable capacity compressors allow you to adjust capacity in minor increments over a wide operational range, giving you excellent control over the humidity and temperature levels in your home. In this way, you can regulate the heating and cooling very precisely; the whole house can be kept at the right temperature, and energy can be saved at the same time.

However, Variable capacity compressors have high costs than single or two-stage compressors. The main advantage of these compressors is that they consume low energy, lower the monthly energy bills, and are almost two times more efficient than single-stage compressors.

Read Also: Different Types of Positive Displacement Pumps

Advantages and Disadvantages of Scroll Compressors

Advantages of Scroll Compressor

- The scroll compressor has more reliability because it has fewer rotating components than the reciprocating compressor.

- These compressors have a compact design.

- They have smooth operating and don’t need spring suspension.

- Scroll compressors are smaller than screw compressors.

- This compressor generates low noise and vibration than the reciprocating compressor.

- As the compressor selects to operate at the selected capacity, the isentropic efficiency of the scroll compressors is more than the isentropic efficiency of the reciprocating compressors. In this case, the scroll compressor is more efficient because it doesn’t contain a dynamic discharge valve that causes additional acceleration losses.

- Depending on the application nature, the scroll compressors don’t require a suction valve but may or may not have a discharge valve.

Disadvantages of Scroll Compressor

- These compressors don’t have easy maintenance and repair.

- They can’t rotate in both directions while reciprocating compressors can rotate in both directions.

- Scroll compressors have high costs.

Applications of Scroll Compressors

- Scroll compressors are most commonly used in HVAC systems.

- They also use in vacuum pumps.

- These types of air compressors are employed on marine, industrial and residential containers.

- This compressor uses as a supercharger in the automobile.

- Employed for food and food refrigeration.

Scroll Compressor VS Reciprocating Compressor

| Scroll Compressor | Reciprocating Compressor |

|---|---|

| A scroll compressor uses scrolls or spirals to compress the fluid. | A reciprocating compressor uses a piston, plunger, or diaphragm to compress the fluid. |

| It has fewer moving parts than the reciprocating compressor. | It has more moving parts. |

| It has a small size. | The reciprocating compressor has a large size. |

| It generates low noise and vibration than the reciprocating compressor. | It generates extreme noise and vibration. |

Read Also: Working of Reciprocating Compressor

| Scroll Compressor | Screw Compressor |

|---|---|

| A scroll compressor uses scrolls for air or gas compression. | A screw compressor uses screws for air or gas compression. |

| For industrial applications, scroll compressors are less efficient than screw compressors. | Screw compressors are best suitable for industrial applications. |

| They have less power than the rotary screw compressors. | They are very powerful. |

| These compressors can’t cool a large of air as screw compressors. | The screw compressors have the capacity to cool more air than the scroll compressors. |

| They are ideal for hospitals or labs. | They are ideal for big factories. |

Read Also: Working and Types of Screw Compressors

FAQ Section

Which is most efficient, scroll compressor or reciprocating compressor?

The scroll compressor is 10% to 15% more efficient than the reciprocating compressor when it works as a single-speed machine. The volumetric efficiencies of these compressors provide them more heating capacity and less capacity variation than the traditional compressors.

How long does a scroll compressor last?

If you properly repair and maintain your AC compressor, it can properly work for up to 10 to 15 years. However, the service life of a well-maintained scroll compressor of the HVAC system is 15 to 20 years.

What is the difference between piston compressor and scroll compressor?

The absence of valves is a distinctive feature of the scroll compressor, setting it apart from the piston compressor, which necessitates both suction and discharge valves. This characteristic of the scroll compressor removes any potential valve losses. Consequently, scroll compressors inherently demonstrate an efficiency advantage of 10% to 15% over piston compressors.

Read Also

- Different types of Compressors

- Types of Dynamic Compressors

- Types of PD Compressors

- Working of Diaphragm Compressor

- Working of HVAC System